ABOUT US

As a private label Diffusion Textile Manufacturer & Exporters are established in 2018, Covering an area of more than 45,000 Sqft. As in this facility all of our extensive line products such as denim pants, Motorbike jeans and denim bottom garments are produced at our manufacturing plant in Lahore-Pakistan with experienced workforce of over 400+ employees on board makes the denim dream reality everyday, Moreover with a manufacturing capacity of 2.4 Million pieces per anum, Diffusion Textile is committed to manufacture and export denims of an unparalleled quality.

Established in 2018, Diffusion Textile has grown over the years, not only in size but also in reputation as some of the world’s trusted clients even trust in our production capabilities

Our Mission

As a private label Diffusion Textile Manufacturer & Exporters are established in 2018, Covering an area of more than 45,000 Sqft. As in this facility all of our extensive line products such as denim pants, Motorbike jeans and denim bottom garments are produced at our manufacturing plant in Lahore-Pakistan with experienced workforce of over 400+ employees on board makes the denim dream reality everyday, Moreover with a manufacturing capacity of 2.4 Million pieces per anum, Diffusion Textile is committed to manufacture and export denims of an unparalleled quality.

Established in 2018, Diffusion Textile has grown over the years, not only in size but

also in reputation as some of the world’s trusted clients even trust in our production capabilities

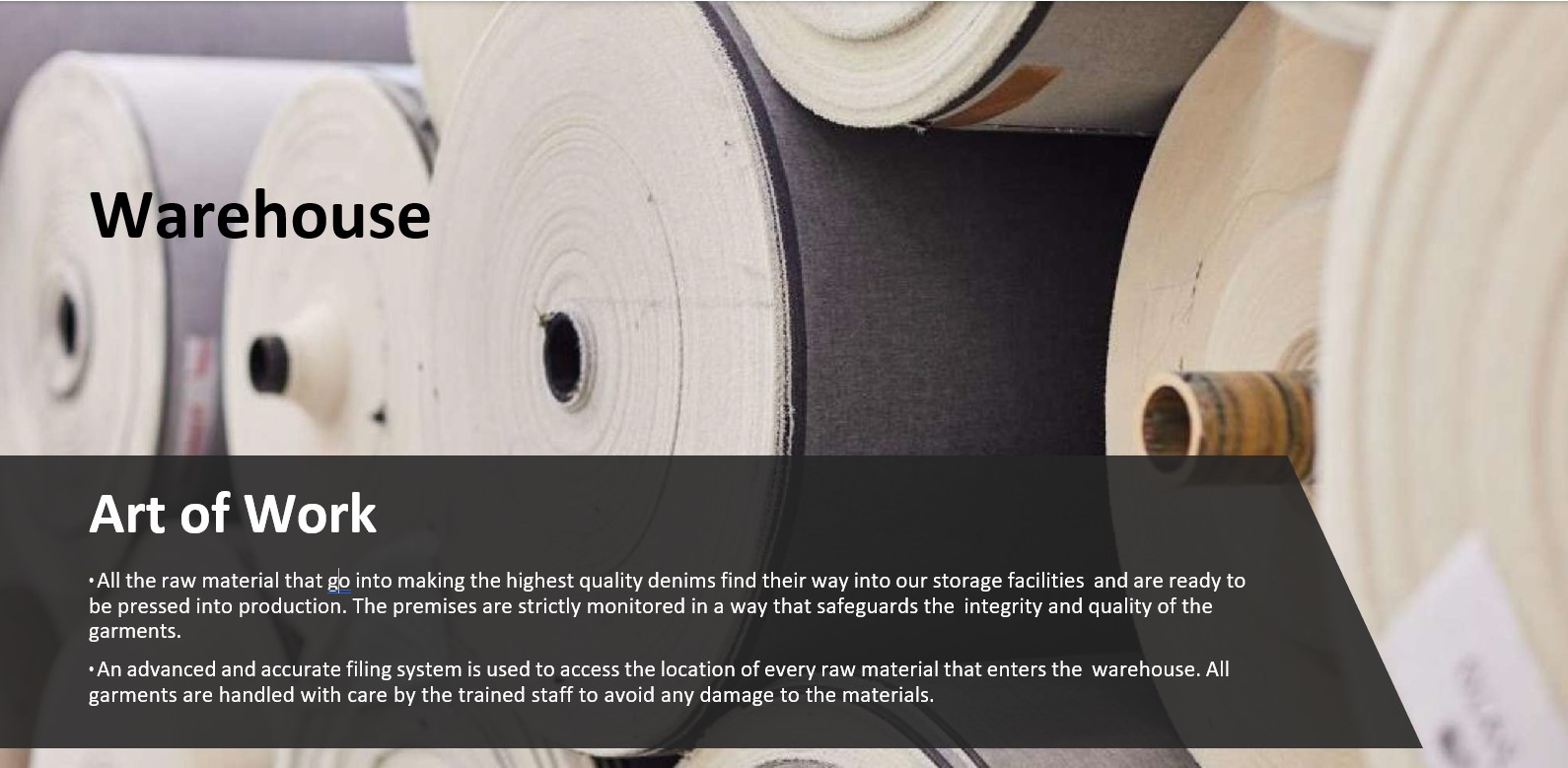

Fabric Check & Planing

Our clients expect nothing but absolute perfection and precision from us. So, when it comes to the fabric used in the denim manufacturing process, we here at Diffusion Textile follow the most uncompromising standards to ensure that even the slightest flaws in fabric are terminated at the initial stage.

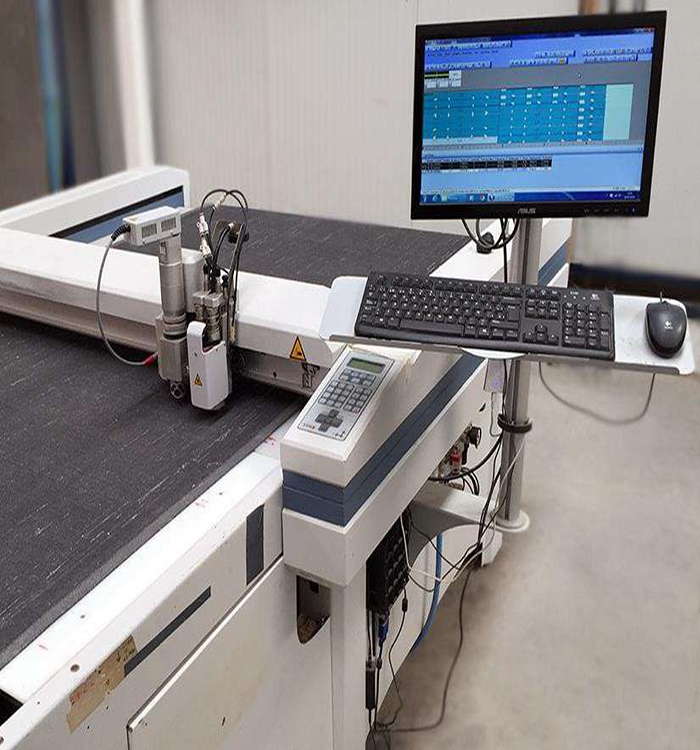

To ensure that only the best quality fabrics reach the production floor, each piece of fabric has to undergo tests that determine its durability, longevity, resistance to tear, smoothness, comfort and other essential qualities Before the materials even enter the floor, the planning team at Diffusion Textile lays out the entire production journey on our advanced CAD (Computer Aided Design) systems. State of the art plotters comes to work here now. This helps to avoid any obstruction or delays and makes the entire denim manufacturing process a smooth ride.

Cutting & Design

In the cutting stage, the raw material starts finding its desired form and shape under an expert supervision. Human and machine come together to execute accurate cuts that ensure the perfect fit our clients are accustomed to.

The pieces of denim are cut with high-speed cutting machines in quick series and large quantities. Specific different and unique cuts come together to create the garment.

Continually, a pair of jeans contains about ten different pieces, from the pockets to the leg panels to the waistband and belt loops.

Finishing & Packaging

It is the little things that make a big difference. The finishing stage is about those finishing touches we give to not only meet the high-end quality, but also the expectations as well as to surpass them every time.

After the washing, the finishing department ensures that any custom changes desired by the clients are carried out. Design adjustments according to the client specifications are then made to the garment and brand labels are added. Garments are then folded, stacked, and placed according to the colors, brand, style, and size.

The product is ready and there’s only one thing left to be done before it heads out for shipping i.e. Packaging. At Diffusion Textile, we ensure the packaging of our products preserves the structural integrity of our garments and saves them from any wear and tear or mishandling. In short we make sure that the accurate item is delivered to our customer who holds our mandate.

Once the packaging is done to the satisfaction, the selected denim garments are put in large shipping cartons and sent to the pre-decided destinations on freight trains, ships, and trucks, whatever the transportation is necessary is taken care off.

Embroidery

Diffusion Textile uses state-of-the-art embroidery printing machines allow us to perfectly stitch your designs onto our denim fabric. Embroidery printing entails sewing a decorative design into a fabric base using a printer that uses cotton thread instead of ink. The result is a beautiful raised image, pattern or lettering that is woven into the fabric.

Traditionally embroidery was a tricky and slow process done by hand but, thanks to technology, it’s now possible to stitch any design flawlessly and in minutes! The results that the embroidery printer produces are simply not possible to achieve by hand or any other printing process.

Using embroidery to give that jacket or vintage pair of jeans a new lease of life. The possibilities are limitless. Our machines create a flawless stitch and can embroider any design or color you can dream up.

We offer great custom embroidery at competitive prices, from 1 item to infinite we will make your idea stitch to life.

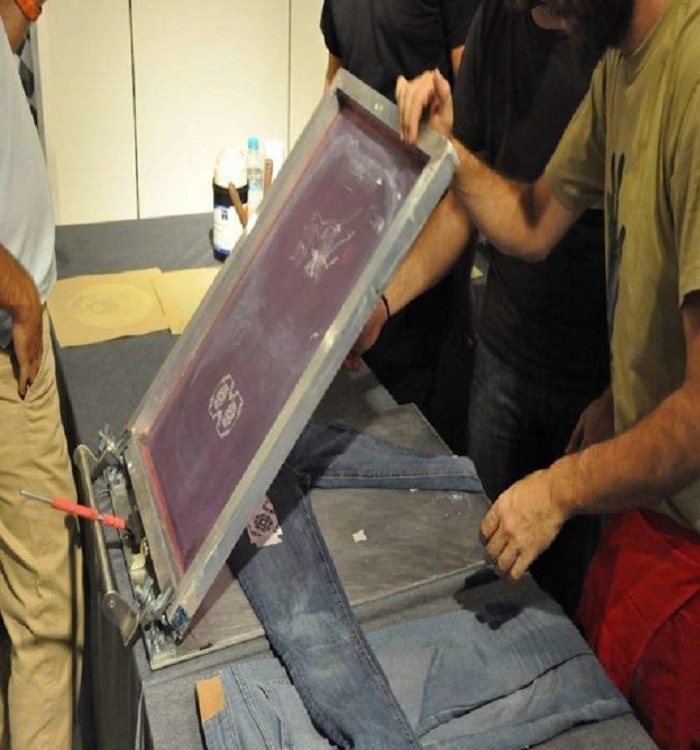

Screen Printing

From the catwalk to the streets, Denim is always in demand! Discover eco-friendly denim at Diffusion Textile, you can print denim effects, including rib effects, floral patterns, embroidery patterns, ripped effects, borders, cross stitches and zip effects. Create custom printed jeans with photo-realistic and creative design styles. Create a totally unique design with the web-to- print platform available at Diffusion Textile. We carry solutions for an array of category products including jackets, jeans/denims, Especially in Denim. Diffusion Textile Printing platforms are equipped to handle any fabric, including denim, cotton, natural and blends. Our cutting-edge printing solutions require only one ink set and do not require pre- treatment or post-treatment. Create beautiful all-over designs or small casual prints that blend well into the fabric.

Why Choose Us

Choose Diffusion Textile for apparel manufacturing excellence that exceeds expectations. With a fusion of innovation and craftsmanship, we tailor every stitch to reflect your vision. Our commitment to quality, sustainability, and timely delivery ensures your brand's success while making a positive impact. Partner with us for garments that not only look remarkable but also tell a story of ethical production and unmatched style.